1.WH-LAB chemical reactor

WH-LAB is a series of microchannel reactors developed by Chemical Reactor, which enjoys independent intellectual property rights. Compared with the traditional batch reaction, the microreactor has the advantages of large specific surface area, high efficiency of mass and heat transfer, high safety, and small amplification effect. It has higher reproducibility, stability, and high efficiency. The micro-reactor has the advantages of low heat buffer requirement, small footprint, high automation, and significant saving of human and material resources. Microchannel reactor based on microfluidic technology represents the development direction of the green chemical industry. The WH-LAB electric chemical reactor developed by Wenhao shares has dramatically reduced the gap between the cathode and the anode, adopted the chip micro channel current pool, significantly accelerated the speed of the cathode and the anode redox improving the efficiency of electrochemical reaction.

Chemical reactor applications: Battery replacement, preparation of particular pharmaceutical intermediates, preparation of energetic materials, and so on.

The WH-LAB chemical reactor process example:

1 the reaction process of continuous flow electrochemistry

Cathodic reduction reaction (one-way circulation)

3 anodic oxidation reaction (one-way circulation)

4 redox (two-way loop)

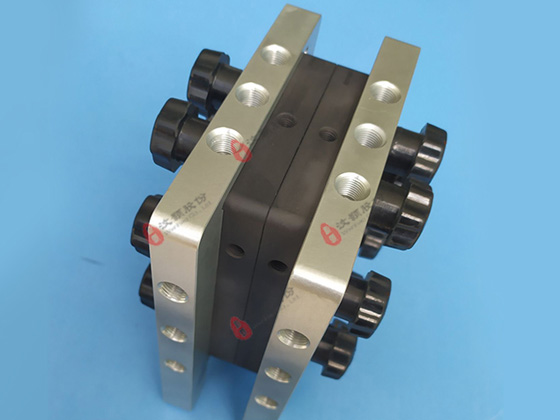

2. Introduction of the WH-LAB Chemical Reactor Module

Dimensions: 120 * 155 * 80

Flow rate: 0-10 ml/min

Electrode material: graphite, foamed nickel, copper, tungsten, etc.

Water-cooled plate material: 6061-T6-Al

Chip material: glass, graphite, nickel, etc.

Circulation pool depth: 100um-2000um optional

Operating Temperature:-25 °C-195 °C;

Operating Pressure: 0-20 bar

Water cooling plate flow rate: 0-10L/min;

Electrode head material: copper thread reinforced electrode head