- Designed to offer excellent mixing and heat transfer for carrying out fast and exothermic reactions on continuous basis in microchannels

- Pressures upto 7MPA

- Flow rate upto 14 l/hr per plate

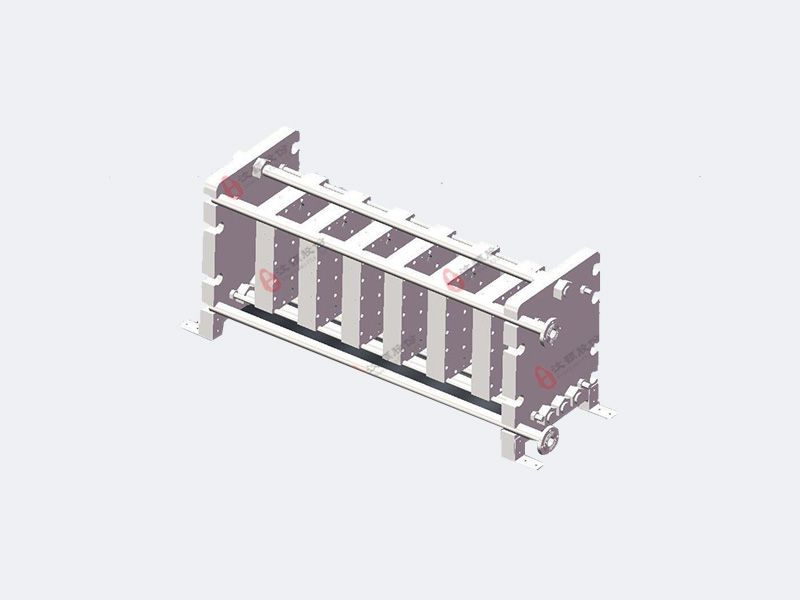

- Modular design to connect upto 12 plates in series or parallel

- Reduced waste and faster transfer of process from laboratory to pilot/commercial scale manufacturing

Advantages of continuous flow reactors over batch reactors:

- Better mixing & very high heat transfer area per unit volume

- Faster reactions & better selectivity.

- Higher yield.

- High safety & ideal for exothermic reactions.

- Reduced waste and faster transfer of process from laboratory to pilot/commercial scale manufacturing

- Easily scalable

Applications:

WH-IND MT280 series is ideal for carrying out a wide range of chemical reactions in the field of pharmaceuticals, fine and specialty chemicals in a continuous manner.

Suitable for

- Homogeneous reactions: Neutralization, condensation, dehydration, photochemical reactions etc.

- Multiphase Reactions: Gas-liquid reactions (G-L): oxidation, ozonolysis, chlorination, etc. Liquid-liquid reactions (L-L): nitration, transfer hydrogenation, sulfoxidation, amination etc. G-L-S and L-S catalytic reactions: esterification, hydrogenation, condensation, etc.

Flux:0~300ml/min

temperature:-30to280℃

liquid holdup:20ml