The etching thickness of AZ photoresist ranges from 1 μm to 150 μm and more.

AZ photoresist features:

Suitable for high resolution (lift-off) processes

For positive/negative graphics

A wide film thickness range

AZ photoresist process conditions:

Pre-bake at 100 °C for 60 seconds (DHP)

Exposure: 1 line step exposure machine/contact exposure machine

Reverse Baking: 110 ~ 125 °C 90 seconds (DHP) : deionized water 30 seconds

Total Exposure: 310-405nm (full exposure under exposure light)

Development: AZ300 MIF developer (2.38%)23 °C 30 ~ 60 seconds Puddle

AZ Developer (1:1)23 °C 60 seconds Dipping

AZ 400K (1:4)23 °C 60 seconds Dipping

Rinse: Deionized water for 30 seconds

Bake at 120 °C for 120 seconds (DHP)

Stripping: AZ stripping solution or oxygen plasma ashing

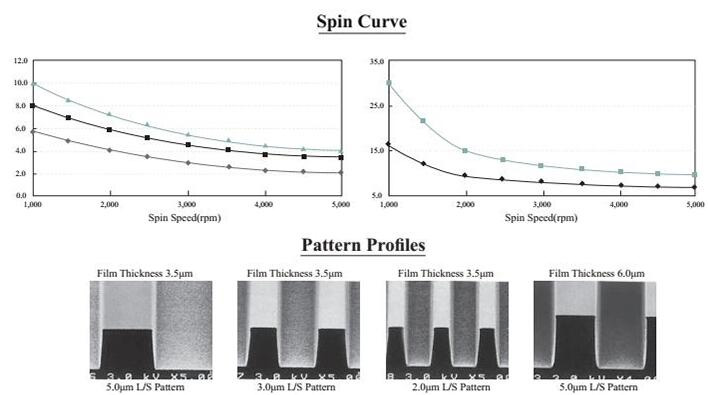

| Name of photoresist | Type | Spin thickness |

| Merck AZ Positive/negative interchangeable photoresist | AZ 5214 | 0.5-6um |

| AZ 50XT Positive glue | AZ 50XT | 40-80um |

| AZ 9260 Positive glue | AZ 9260 | 6.2-15um |

| AZ 4620 photoresist | AZ 4620 | 10-15um |

| MicroChem SU-8 Negative glue | SU-8 2015 | 13-38um |

| MicroChem SU-8 Negative glue | SU-8 2050 | 40-170um |

| MicroChem SU-8 Negative glue | SU-8 2075 | 60-240um |

| MicroChem SU-8 Negative glue | SU-8 2150 | 190-650um |

| MicroChem SU-8 Negative glue | SU-8 3010 | 8-15um |

| MicroChem SU-8 Negative glue | SU-8 3050 | 44-100um |

The etching thickness of AZ photoresist ranges from 1 μm to 150 μm and more. High sensitivity, high yield, high adhesion, especially for wet etching process improvement, widely used in the global semiconductor industry.

Type and parameter of photoresist