A syringe pump is a little, positive-removal siphon used to steadily move exact volumes of liquid. Chemyx Fusion Series syringe pump are totally determined through a stepper engine.

A lead screw, strung through a pusher block, unequivocally turns the syringe pump engine. This causes the pusher square to move.The liquid launches at an exact and exact rate during implantation syringe pump mode, when the pusher block pushes against the unclogger of a got needle. Sections on the pusher block hold the unclogger of the needle for withdrawal abilities.

At the point when the syringe pump turns the other way, the pusher block moves with the end goal that the needle unclogger is pulled, hence bringing liquid into the needle. For our syringe pump, the pusher block moves to the ideal for imbuement and to one side for withdrawal.

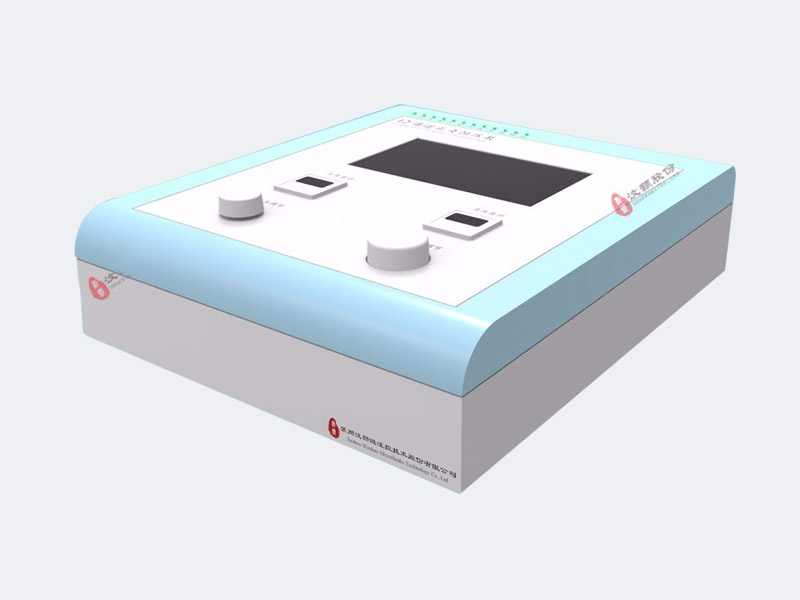

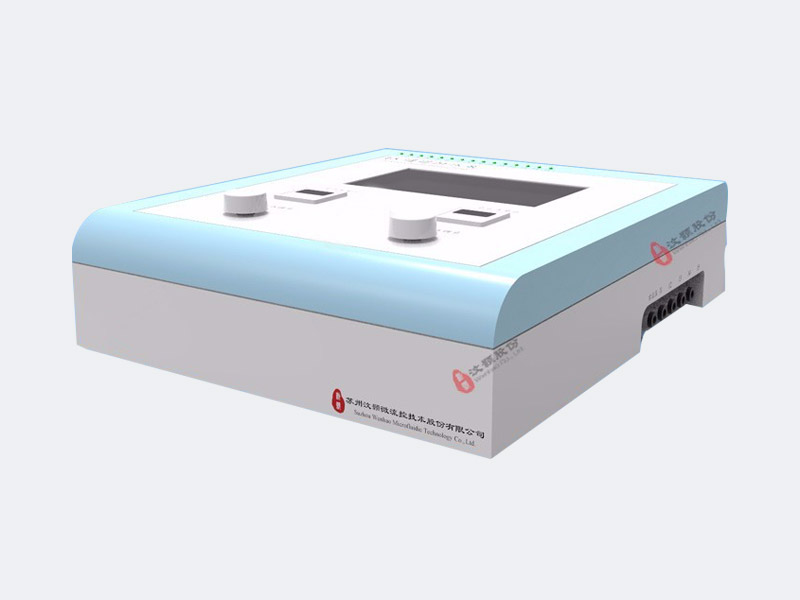

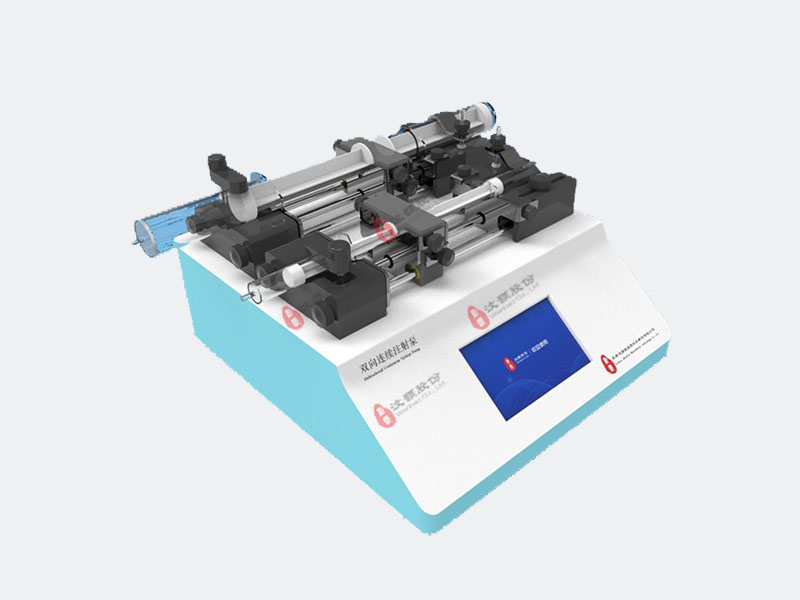

This is a high-accuracy liquid control gear autonomously created by syringe pump supplier and syringe pump manufacturer, Wenhao Co., Ltd. This framework has the attributes of accuracy, soundness, and solid enemy of impedance capacity, and can be generally utilized in related fields, for example, microfluidic drive control.

It contains two-way drive modules, and the changing valve of every way just should be associated with a basic pipeline to acknowledge ceaseless fluid infusion. Simple to utilize and easy to work. The boundary setting, alteration and perspective on liquid control by syringe pump supplier and syringe pump manufacturer can be finished in the primary point of interaction of firing up.

During boundary input, the model and internal measurement of the pump can be chosen straightforwardly from the rundown, or physically info, and afterward input different boundaries, the assignment by syringe pump supplier and syringe pump manufacturer can be stopped whenever during the work, and different boundaries can be reset and executed right away.

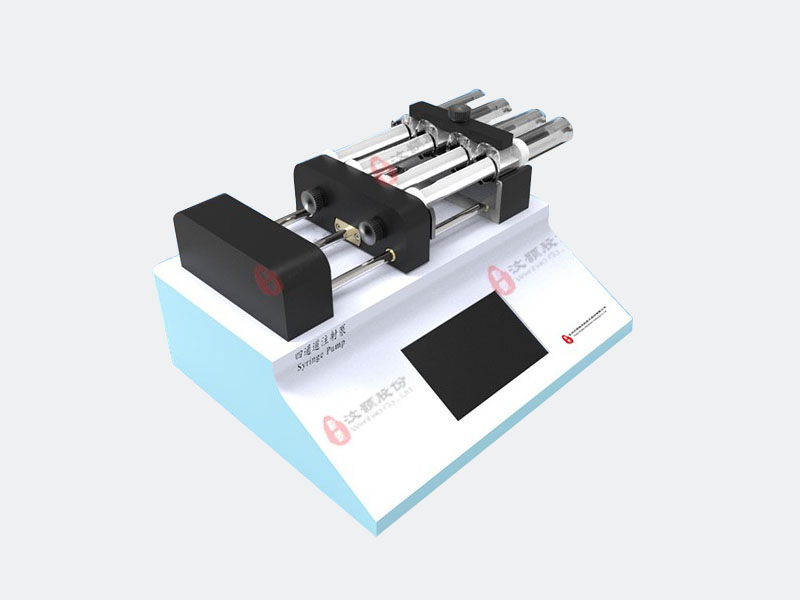

All our syringe pump frameworks have a solitary lead screw strung through a pusher block. The syringe pump block moves when the lead screw turns. The two aide poles keep the pusher block even and totally opposite to the lead screw. The square delivery button separates the pusher block from the lead screw.

Syringe pump supplier and syringe pump manufacturer moves the pusher square to another situation by holding down the button. Delivering the button will lock the pusher block once again into the right spot.

Syringe pump supplier and syringe pump manufacturer put the needles on the needle holder block in the angular sections, or channels, and hold safely utilizing needle clips.

FAQ

What is the safe practice in syringe pump management?

Syringe pump are utilized as a feature of palliative consideration to oversee prescriptions subcutaneously to patients who can’t oversee or endure oral drug. Wandering syringe pump are compact battery-worked gadgets for conveying medicine by consistent subcutaneous implantation (CSCI) throughout a given time-frame (generally 24 hours).

Syringe pump are valuable when little volumes of medications should be implanted at a sluggish rate and their minimal plan empowers patients to move around and keep up with autonomy . The syringe pump are easy to work, yet preparing is fundamental.

Patients, carers and wellbeing experts regularly wrongly related microfluidic syringe pump and independent syringe pump with fast approaching demise, yet the gadgets might be utilized whenever in the consideration pathway to control manifestations where medications can’t be managed orally, for example, in patients with obstinate sickness and heaving – records signs for their utilization.

It is thusly significant while beginning a siphon to offer patients and their families consolation and clarify the requirement for the microfluidic syringe pump and independent syringe pump .

Microfluidic syringe pump and independent syringe pump k microfluidic syringe pump and indepeeps a consistent serum level of prescriptions, which accomplishes preferable manifestation command over irregular dosing.

It additionally decreases the need to utilize less famous courses of organization, for example, rectal or intravenous.endent syringe pump records the benefits and disservices of CSCI.

What are the different types of microfluidic syringe pump and independent syringe pump ?

There are multiple ways of directing the progression of fluids through microfluidic syringe pump and independent syringe pump . With regards to the development of liquids, the two significant sorts of liquid exchange pump are positive uprooting siphons and non-positive removal pump.

There are different types of microfluidic syringe pump and independent syringe pump that have been utilized over the course of the years to work with the progression of fluids through a microfluidic framework or gadget. In this article we center around the generally utilized 3 systems/siphons:

Peristaltic pump

A peristaltic siphon applies microfluidic syringe pump and independent syringe pump to a mechanical activity on an adaptable cylinder that associates the liquid supply to the microfluidic device.This power assists the fluid with moving from the from the entry of the cylinder to the exit

Syringe pump

This microfluidic syringe pump and independent syringe pump instrument additionally utilized a mechanical activity on an unclogger that applies power on a needle containing the fluid.

Because of this movement, the liquid can move from the needle spout, through the tubing, and into the microfluidic syringe pump and independent syringe pump. The development of the unclogger is constrained by a perpetual screw that can be tuned as expected for a particular analysis.

Microfluidic precision pump

The last, and most proficient microfluidic syringe pump and independent syringe pump for use in a wide range of tests is a strain driven stream control siphon. This microfluidic siphon is a sort of pneumatic siphon framework created by Wenhao.Co.

microfluidic syringe pump and independent syringe pump utilize an outside pressure source, that is associated with a fixed fluid repository. The siphon applies a gas pressure which moves the fluid through the tubing and into the microfluidic gadget.

The framework is planned by syringe pump supplier and syringe pump manufacturer around two strain sources – the P out, and the tension inside the fixed supply (P in). The course and stream pace of the fluid is controlled involving the distinction in strain between P in and P out.

Syringe pump supplier and syringe pump manufacturer stream pace of the fluid is straightforwardly relative to the tension contrast. To ascertain the stream pace of the fluid is performed with the assistance of this recipe given underneath, that fuses the utilization of microfluidic opposition (R) as the proportionality coefficient.

The microfluidic obstruction coefficient of a particular microfluidic framework is determined by syringe pump supplier and syringe pump manufacturer in light of the gadget calculation, and properties of the fluid being utilized.

What are the differences between syringe pump vs infusion pump?

A significant number of the Syringe pump china companies utilized during basic sickness are exceptionally powerful. Change in the pace of Syringe pump china company by a couple of ml each hour can have extremely huge impacts. Patients regularly have a few different prescription mixtures running simultaneously.

Thusly, precision in the conveyance of liquid and drugs is vital. To guarantee exact liquid and medicine organization, Syringe pump china companies are utilized to convey intravenous treatment.

A infusion pump draws liquid from a standard pack of intravenous liquid and controls the pace of the stream. It gives exact and consistent treatment. Since Syringe pump china company can utilize any size pack of intravenous liquid, an infusion pump can be utilized to convey liquids at either an extremely sluggish or exceptionally quick implantation rate.

Syringe pump china company can handle a solitary intravenous line, though, other implantation siphons have 3 siphons incorporated into one gadget. These “triple siphons” are utilized by Syringe pump china company to save space.

The syringe is an alternate sort of implantation conveyance gadget. Rather than drawing liquid from an implantation pack, intravenous meds are brought into a needle and introduced into the gadget. Since needle siphons contain a most extreme volume of 50 ml, needle siphons are utilized to regulate meds that have tiny hourly volumes (for instance, generally under 5 ml/hr). Assuming that the hourly volume prerequisites increment, a mixture siphon is by and large used to convey the medicine. Needle siphons are designed by Syringe pump china company for more minimized and occupy less room than imbuement siphons. This becomes significant when the Syringe pump china company is on various implantations.

In the event that a patient has exceptionally high liquid prerequisites, or is cold (hypothermic), a unique imbuement siphon with an implicit warmer can be utilized. This gadget is utilized most often in injury patients who are cold and need a lot of liquid or potentially blood items.