Polydimethylsiloxane (PDMS), otherwise called dimethylpolysiloxane or dimethicone, has a place with a gathering of polymeric organosilicon intensities that are ordinarily alluded to as silicones. PDMS is the most broadly utilized silicon-based natural polymer, as its adaptability and properties lead to numerous applications.

It is especially known for its strange rheological properties. PDMS is optically clear and, as a rule, inactive, non-poisonous, and non-combustible. It is one of a few kinds of silicone oil (polymerized siloxane). Its applications range from contact focal points and clinical gadgets to elastomers; it is likewise present in shampoos (as it makes hair glossy and elusive), food (antifoaming specialist), caulking, greases and hotness safe tiles.

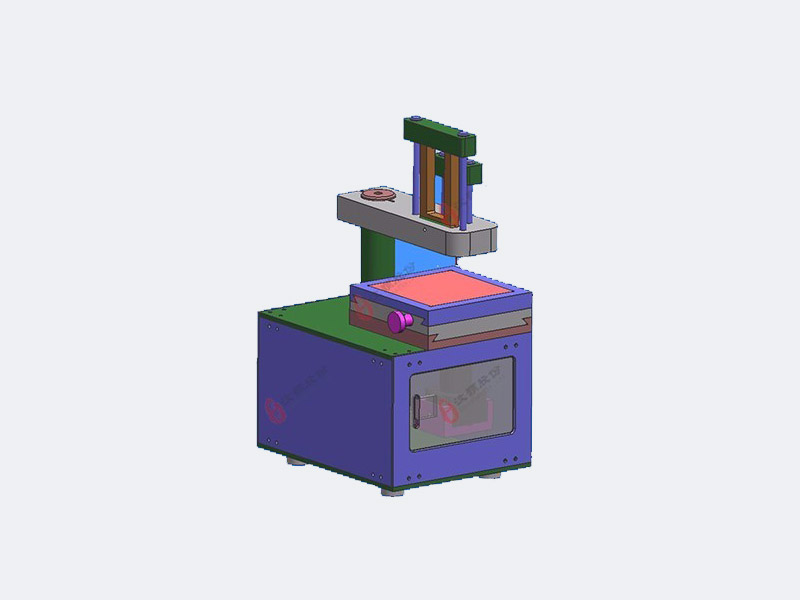

Soft chips (particularly PDMS chips) are inclined to lopsided front line and burrs on the bleeding edge during the cutting system. pdms cutter can take care of the above issues and can slice delicate chips to a foreordained size. pdms cutter is worked by a mechanical construction, which saves exertion and decreases the opportunity of lopsided cutting.

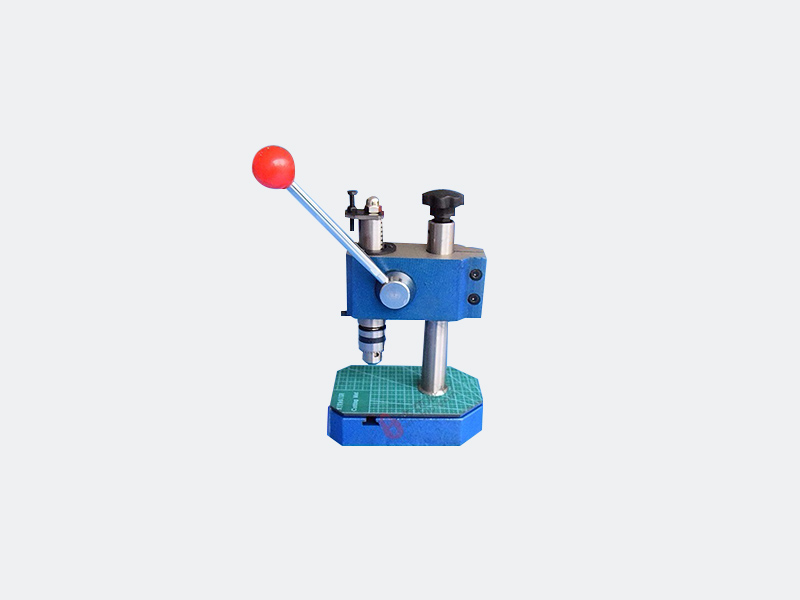

pdms puncher comprises an empty needle and a hand grasp tube. The empty needle is chamfered by mechanical chamfering, and the opening measurement acquired by punching is predictable with the internal breadth of the needle. Ergonomic plan of the pdms puncher, simple to utilize, contrasted with a basic punch, punch further, more straight.

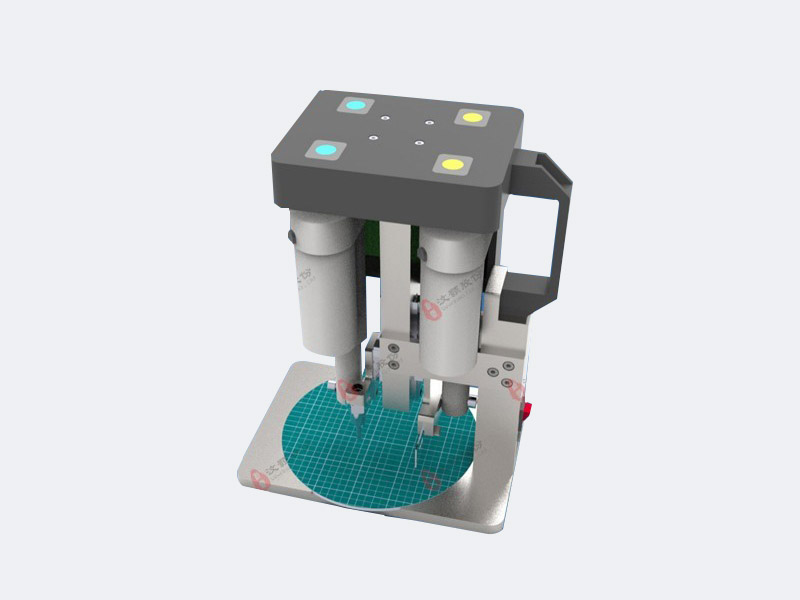

Our pdms chip cutting and puncher can cut and punch both delicate chips like PDMS. The pdms chip cutting and puncher can fix the punch head and the cutting edge on the instrument’s upper part, and the edge’s stature and the sharp edge can be changed.

The squeezing handle can upward poke holes and cut chips. Especially significant is that the pdms chip cutting and puncher is furnished with a magnifying lens, the area of penetrating and cutting neighborhood intensification, in the X-Axis tweaking gadget helped with accomplishing accuracy cutting and situating boring, pdms chip cutting and puncher utilizing mechanical construction plan, with work saving, arrangement is more advantageous, decrease cutting isn’t perfect, state of the art burr, etc.

Post-cure pdms chip cutting and puncher preparation and hole punching

When the PDMS is relieved, utilize a pdms cutter to painstakingly cut around the outside of the silicon wafer (yet on the actual wafer).

pdms cutter utilizes the edge of the surgical blade or a comparable apparatus, gradually and cautiously lift the edge of the PDMS off of the wafer. When it gets sufficiently high off the outer layer of the pdms cutter, utilize your hand to gradually strip it off the remainder of the way.

Little elements can be better safeguarded by first putting a ml of so of ~70% ethanol in water on the highest point of the PDMS close to where you will pull it off the wafer. While pulling the PDMS off the shape, the ethanol diminishes the surface pressure between the PDMS and the pdms cutter form, keeping the PDMS from staying. In the case of doing this progression, utilize a perfect room quality air blower to get the ethanol off the PDMS and pdms cutter to continuing to the following stage

Utilize pdms chip cutting and puncher cover the whole underside of the PDMS containing the channels, with the goal that they don’t get canvassed in soil.

PDMS can be put away like this for months or years. Simply make a point to clean the outside with pdms chip cutting and puncher utilizes to eliminate any residue development.

Put the pdms chip cutting and puncher onto a delicate surface, for example, a silicone sheet or an extra piece of PDMS.

We utilize an enormous fridge magnet with a delicate back in my lab, yet PDMS works similarly too. The objective is to not let the punching tool get dull, as it will make openings in the PDMS that are more modest and dirtier. This makes it harder to get the tubing into the openings while running the gadget and furthermore can allow PDMS to garbage enter the channel.

- Utilizing a pdms cutter, poke holes the entire way through the PDMS at the inlet and outlet of the gadget. Push the unclogger so that the poked PDMS exits the hole punch through the tape side of the PDMS gadget. You can lift the PDMS somewhat while doing this to assist the PDMS with punching exit through the tape side.

FAQ

Benefits of pdms cutter and pdms puncher?

1) The verticality of cutting utilizing this strategy is generally high;

2) The pdms cutter and pdms puncher is more steady as the handle is weighty;

3) Directly add a slicing head to alter the work area pdms puncher to understand the multi-capacity of the work area puncher.

Why use PDMS for pdms puncher fabrication?

PDMS was picked to make microfluidic chips fundamentally hence:

It is straightforward at optical frequencies, pdms puncher works with the perception of substance in miniature channels outwardly or through a magnifying lens.

It has a low autofluorescence

It is considered as bio-viable (for certain limitations).

The PDMS bonds firmly to glass or another PDMS layer with a straightforward plasma treatment. This permits the development of multi-facet PDMS gadgets to exploit the mechanical potential outcomes presented by glass substrates, like the utilization of metal testimony, oxide affidavit or surface functionalization.

PDMS, during cross-connecting, can be covered with a controlled thickness on a substrate utilizing a basic spin coat. This permits the manufacture of pdms cutter and pdms puncher and the mix of miniature valves.

pdms cutter and pdms puncher is deformable, which permits the coordination of microfluidic valves utilizing the misshapening of PDMS miniature channels, the simple association of watertight fluidic associations and its utilization to identify extremely low powers like biomechanics communications from cells.

pdms cutter and pdms puncher is economically contrasted with recently utilized materials (for example silicon).

pdms cutter and pdms puncher is likewise simple to form, in light of the fact that, in any event, when blended in with the cross-connecting specialist, it stays fluid at room temperature for a long time. The PDMS can shape structures at high goals. With some enhancement, it is feasible to shape designs of a couple of nanometers.

pdms cutter and pdms puncher is gas penetrable. It empowers cell culture by controlling how much gas through the material or impasse channels filling (remaining air rises under fluid tension might escape through PDMS to adjust air pressure).