Hard polymer chip batch injection molding/bonding

Injection molding, refers to the temperature, through the screw stirring completely molten plastic material, with high pressure into the mold cavity, after cooling and curing, to get the molding products method. This method is suitable for mass production of complex parts and is one of the important machining methods. There are mainly closing mold, injection, pressure, cooling, mold opening, products out of 6 stages. The injection molding of microfluidic chip, with strong product consistency, higher efficiency and more suitable for mass production, has attracted more and more attention.

Wenhao shares specializes in the development and application of micro-flow control technology, has a strong precision mold design, mold opening, product batch injection molding, subsequent product sealing treatment of professional technology and production team, can meet the needs of customers for injection molding batch production.

Microfluidic chip injection molding processing capacity:

● Chip material: polymer (including PC, PS, PP, PMMA, COC, COP, etc.)

● Runner size: ≥100 m

● Depth to width ratio of runner: minimum 1:1

● Flow mold accuracy: <±10%

● Optimum accuracy: ±6 m

● Routine injection mold times: 300,000 molds

● The number of microinjection molds: 50,000

● Injection molding mass production capacity: 10 million pieces/year

Business process: customer communication — chip mold opening evaluation — mold design — experimental mold opening — mold trial — mold repair — sample submission for customer confirmation — batch injection molding — batch sealing — Product quality inspection — chip finished product delivery. Details are as follows:

1. Customer’s demand for mass production of microfluidic chips

Customer’s demand for mass production of injection molding of microfluidic chip:

1) The client shall provide the microfluidic chip design drawings. According to the chip design drawings and the client’s chip design objectives, the technician shall evaluate the chip design drawings and determine the chip design drawings together with the client;

2) The client provided the function of the chip to be realized. He hao technical staff designed the chip according to the function, and evaluated the function realization of the chip, and determined the chip design drawing together with the client.

Ii. Feasibility evaluation of injection mold opening

Injection mold development based on chip drawing technology assessment, such as the appearance of the microfluidic chip, material quality, the total thickness, and the size of the channel, deep wide than the dimensional precision, tolerance, surface finish, mould inlet way, product configuration, product to take out the plunger in the mould configuration, such as chip subsequent sealing requirements, all aspects have open mold injection molding feasibility evaluation.

Iii. Signing of sales contracts

After the completion of the evaluation, it is determined that the injection molding can be realized according to the customer’s requirements and the contract can be signed with the customer.

Four, mold design and development

According to the customer’s requirements, based on the experience of injection molding of microfluidic chip, a full range of preliminary evaluation of mold design. According to the mold evaluation data in the early stage, the technical team carried out mold cooling water channel design, product gate layout design, product extraction design in the mold, mold two-plate or three-plate mold design, mold sliding block design, exhaust slot design.

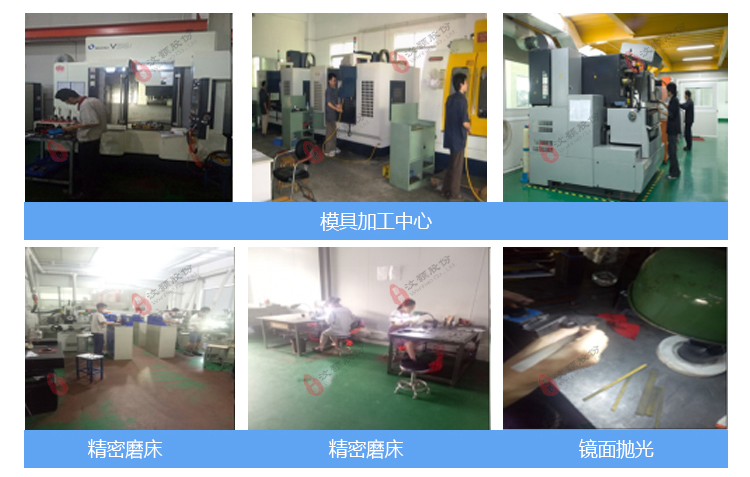

Five, mold processing

Makino V33i and V56i high-speed CNC machining centers and other imported equipment are used to ensure the machining accuracy of mold parts.

Mold processing center

Vi. Mold trial and sample sending

Vi. Mold trial and sample sending

After the mold is assembled, conduct injection test. After the test, measure the appearance and size of the test product. If there are any unqualified items, repair the mold, and try again after the repair. In the mold verification stage, the problems encountered in mass production of microfluidic chip can be solved. Through professional theoretical knowledge and practical experience, the microchannel of microfluidic chip products formed by precise injection molding can achieve the characteristics of small size deviation, high precision and strong consistency. After the mold tries to meet the set parameters of the microfluidic chip, provide 10-30PSC samples for customers to sign samples.

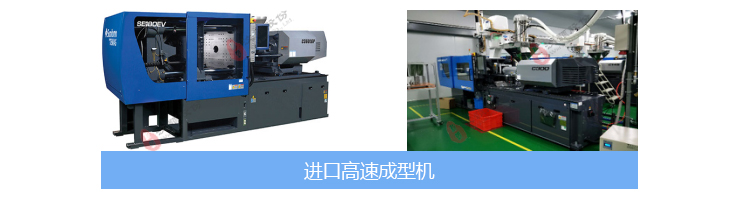

Batch production of injection molding of microfluidic chip

After customer orders are placed, imported high-speed molding machines and modern production workshops are used to ensure the high quality of products. During the production process, the quality of products is under real-time control according to customer requirements.

Import high speed molding machine

Import high speed molding machine

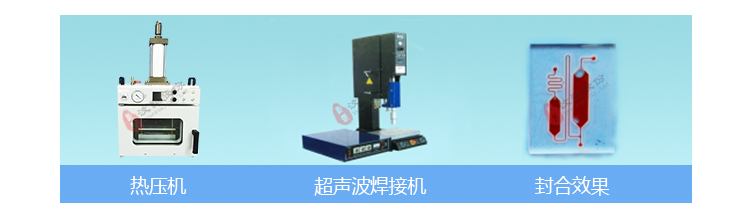

Eight, chip post-processing

After injection molding, sealing, hydrophilic, hydrophobic, sterilization and other treatments are carried out according to customer requirements. For example, the key process of chip sealing can provide a variety of sealing methods for perfect sealing according to the characteristics of chip products, with a high first-success rate, such as ultrasonic sealing, hot press sealing, or adhesive sealing and other sealing methods, to meet the different sealing requirements of various products.

Chip post-processing

Chip post-processing

Ix. Product quality inspection

The quality control team USES fully automated inspection equipment to conduct inspection in the automated injection molding process. After the product is sealed, product quality control is carried out through product quality inspection, warehousing inspection and outgoing inspection.

Product quality inspection

Product quality inspection

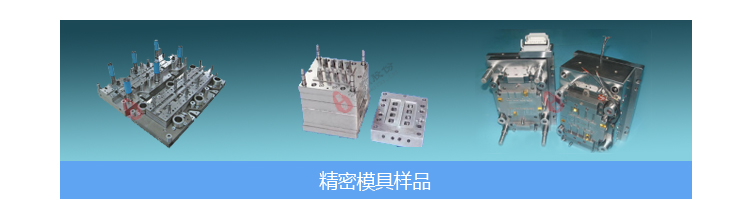

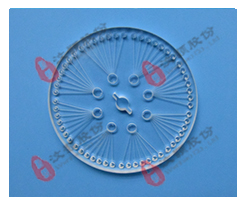

X. Precision mold

Precision mold sample

Precision mold sample

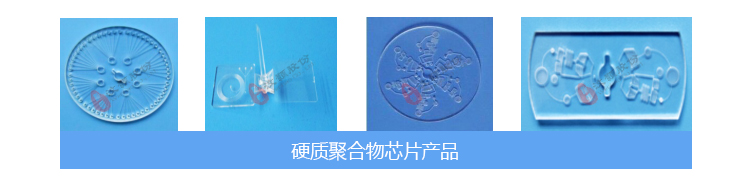

11. Chip sample

Hard polymer chip products

Xii. Injection molding cases

Xii. Injection molding cases

The project successfully developed and designed precision mold for a domestic university, and mass produced microfluidic chip.

PMMA injection molding

● A high precision mold for 100um x 100um micro flow channel was successfully developed

● Through careful mold design, successfully overcome the product from 4mm thickness to 0.6mm large gap in the forming problem

● through high precision mold kernel processing, meet the micro flow path ±7um tolerance requirements

● Through the import of high-precision machining center, to meet the consistency of the precision of a number of micro-channel die

● the polishing of the mold kernel and the choice of materials, well meet the product transmittance > more than 92%