Fabrication of PDMS Chip—-injection

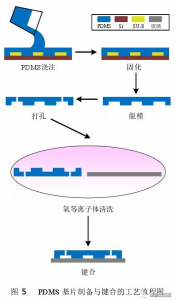

After the male-die mold is finished, the next step is to fabricate the PDMS chip in micro-channels by the molding method. The main principle of the molding method is to pour PDMS onto the mold and then solidify it. Then, the separated PDMS substrate bonded to the glass to form a microfluidic chip. The detailed production process is shown in Figure 5

(1) Immersion release agent: immerse the male-die mold in a solution of release agent for 15 minutes

And then put it into a Petri dish and put it into an oven at 80 °C for drying. Because the Petri dish material is plastic, the oven temperature can not be too high.

(2) PDMS prepolymer configuration: put the plastic cup on the electronic scale and clear the scale. Pour a certain amount of PDMS reagent into the plastic cup, calculate the mass of curing agent according to the mass of PDMS reagent, clear the skin again, and drop 1/10 mass of curing agent into the plastic cup with another clean dropper. After the PDMS and the curing agent are mixed, stir it for 10 minutes to evenly distribute the tiny bubbles in the plastic cup.

(3) PDMS prepolymer vacuum treatment: put the PDMS prepolymer with tiny uniform bubbles in

a vacuum drying box, slowly vacuum until tiny bubbles are expelled. In the vacuum process, if the reagent is out of the plastic cup edge of the situation, you need to turn off the vacuum pump many times to avoid reagent out of the container.

(4) PDMS prepolymer pouring: the mold is placed horizontally in a plastic petri dish, and then pour the configured PDMS prepolymer into a plastic petri dish. In the process, pour the PDMS from the middle of the mold and then diffused it until the PDMS completely covers the mold to a certain height. Since a small number of bubbles will form during the pouring of PDMS, step (3) needs to be repeated.

(5) PDMS prepolymer curing: after the bubble has completely disappeared, place the plastic Petri dish in the oven at 75 °C, leave the PDMS prepolymer in the oven for 3 hours. After the PDMS prepolymer is cured, please remove it from the oven.

(6) PDMS prepolymer demolding: use a small knife to cut the PDMS curing film along the edge of the mold, then removed the mold with the PDMS curing film covered above it. Be careful when demolding to avoid the risk of flow channel edge rupture.

(7) PDMS substrate perforating: use a 1mm diameter PDMS punching machine to perforate the microchannel’s liquid inlet and liquid outlets. When perforating, try to make the perforator perpendicular to the substrate so that the hole is perpendicular.

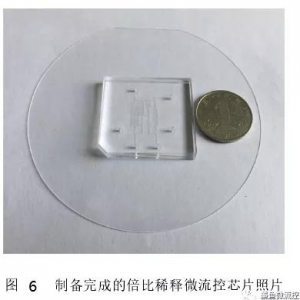

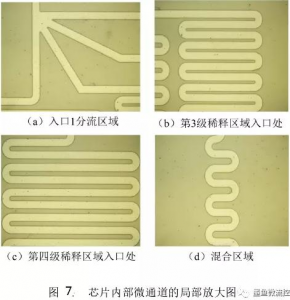

(8) PDMS substrate cleaning and bonding: put the PDMS substrate and the glass substrate required in anhydrous alcohol for 10 minutes by ultrasonic cleaning, remove, and put into the oven for drying. After drying, put the PDMS microchannel into the oxygen plasma cleaner for 15s with the glass cover. The PDMS substrate and the glass substrate are aligned, and bond together, and the surface of the PDMS substrate is pressed gently with tweezers to seal the PDMS onto the glass irreversibly. After bonding, place the microfluidic chips in a vacuum drying chamber at 65 °C for 30 min, and finally, the microfluidic chips were fabricated, as shown in Fig. 6. The chip is placed under a microscope to check its structural integrity. Fig. 7 shows a partial enlargement of some of the critical structures of the chip.